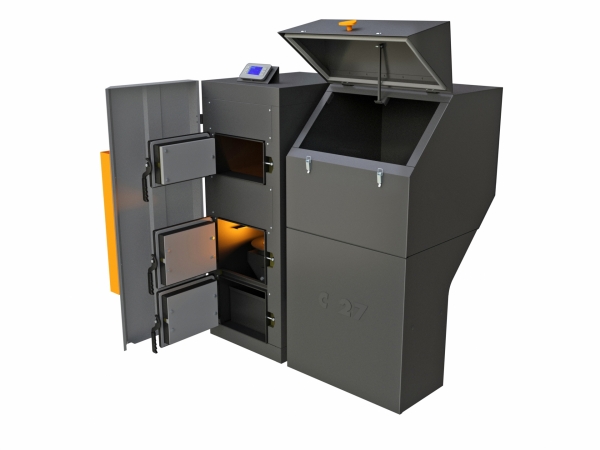

BENEKOV C 27

The BENEKOV C 27 boiler is the first Czech automatic boiler for coal in the 5th category, fulfilling Ekodesign parameters. It is suitable for heating premises where the demand for heat performance does not exceed 25 kW. It is a first class and very efficient automatic boiler for soild fuel (coal, wooden pellets).

| Výkon | 25 Kw |

| SVT | SVT20001 |

| Hmotnost | 425 kg |

| Objem zásobníku | 260 l |

| Rozměry | 1279x1036x1490 š x h x v |

| Příkon | 35 W |

| Účinnost | 90 % |

| Ekodesign | ano |

| Vhodné pro RD | ano |

| Třída energetické náročnosti | A + |

| Třída | 4. třída |

| Výkon kotle | Uhlí, dřevěné pelety |

- It is possible to use the BENEKOV C 27 boiler for heating homes, administrative buildings and other premises where the demands for heating performance do not exceed 25 kW.

- The first Czech automatic boiler for coal in category 5, according to Czech Technical Norm ČSN EN 303-5: 2013.

- The first Czech automatic boiler for coal which fulfills Ekodesign parameters.

- The ideal model for the ENERGY EFFICIENT BENEKOV BOILER ROOMS concept.

- The control unit with modulation performance and equithermal regulation comes as standard in this automatic boiler. This saves up to 15% of fuel costs, especially in the transition periods of spring and fall.

- The certified fuels are brown coal nut 2 and wooden pellets. Thanks to the modulation of the performance, the automatic boiler achieves excellent effectiveness above 90% in the whole range of the performance for both fuels.

- 3-thrust construction of the vertical exchanger guarantees high efficiency. It is sufficient to clean the unit once every 4 to 6 weeks.

- In the PREMIUM version, the designer doors of the boiler unit do not come as standard. The EXCLUSIVE version includes design covering doors of the boiler units and also enables remote access to the boiler via Internet.

- The control unit enables the control of 2 heating circuits.

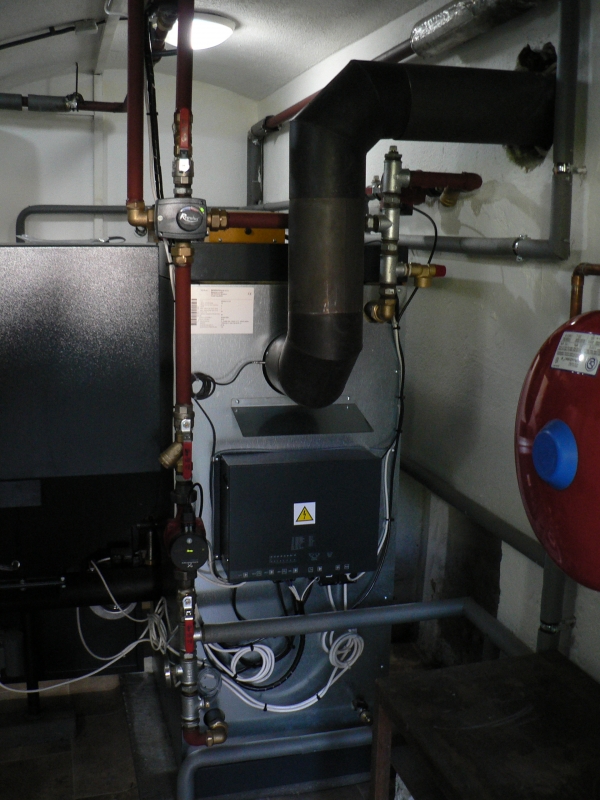

- It is possible to purchase a wide range of accessories for these automatic boilers, like for example, a de-asher, an automatic cleaning exchanger, a back-up power source, a chimney valve, etc.

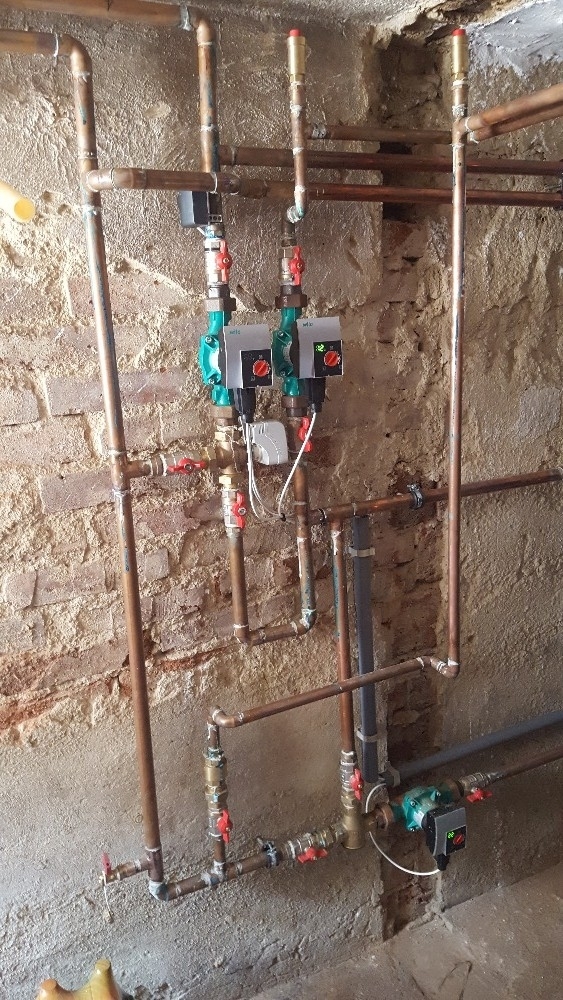

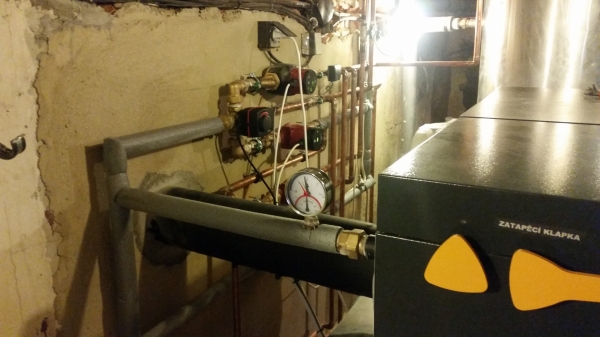

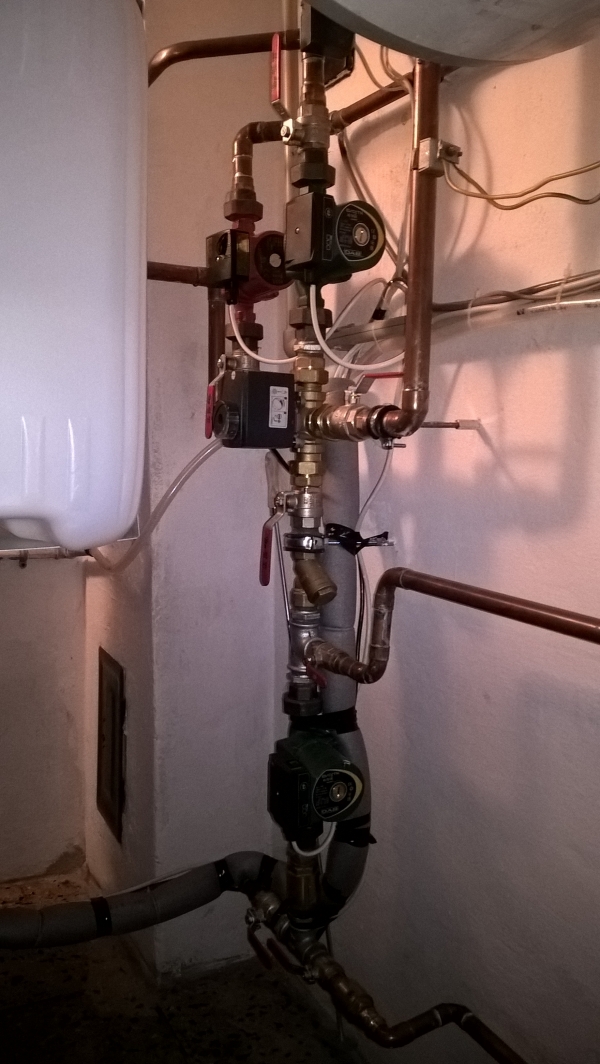

- For a high quality solution of the whole heating unit, we recommend hydraulic components, which are stated in the Technical documentation for the installation of Benekov boilers.

- If the boiler is installed according to the Technical documentation for installing Benekov boilers and the hydraulic components, as defined by the manufacturer, are used, the boiler has an extended 5 year warranty.

- The greatest guarantee of reliability of the used fixtures during installation are the ones used directly from the manufacturer.

- For operating the boiler, we recommend using Ridepal fuel from Ridera, which is available all over the Czech Republic. When burning woodchips, we recommend using BIOMAC woodchips, also available all over the Czech Republic.

On average, it is necessary to service the boiler for 10 minutes a day. The fuel container enables service-free operations for a period of 3 to 7 days.

If coal is burned, it is necessary to remove the ashes once every 3 to 7 days. If woodchips are burned, it is necessary to remove the ashes once every 3 to 5 weeks. The intensity of ash removal depends on the quality of the fuel used and the boiler series.

As with our other products, everyday operation of the boiler is ensured by an emergency thermostat, which serves to protect the heating system against over-heating. The motor of the screw conveyor of the feeding system is equipped with a thermo-fuse against overloading. The safety fuse secures the boiler against fuel burning into the fuel container during longer periods of power outage.

PoptatSuitable connections are defined in the Technical documentation for the installation of BENEKOV boilers.

Poptat

| Weight | kg | 425 |

| Water capacity | dm3 | 89 |

| Chimney diameter | mm | 145 |

| Heat transfer surface | m2 | 2,84 |

| Fuel container capacity | dm3 | 330 |

| Boiler dimensions: width x depth x height | mm | 1279x1036x1490 |

| Size of the fuel container filling gap | mm | 600x340 |

| Class of boiler acc. ČSN EN 303-5 | 5 | |

| Working water overpressure | bar (kPa) | 2,0 (200) |

| Tested water overpressure | bar (kPa) | 4,0 (400) |

| Recommended working temperature of heating water | °C | 65 - 80 |

| Lowest temperature of incoming water | °C | 60 |

| Hydraulic loss of the boiler | ||

| ∆ T = 10 K | mbar | 16 |

| ∆ T = 20 K | mbar | 4 |

| Noise level | dB | < 46 +,- 3 dB (A) |

| Chimney draught | mbar | 0,15 – 0,20 |

| Boiler connectors | ||

| - heating water | Js | G 1” |

| - return water | Js | G 1” |

| Connecting voltage | 1 PEN ~ 50 Hz 230 V | |

| Electric input at nominal power | W | 35 |

| Electric protection | IP 20 |

Documents available for download

Návod k obsluze Benekov C27 (pdf | 0MB) Climatix Premium (pdf | 0MB)Benekov - firma s tradicí

Zkušenost, inovace, flexibilita, komunikace a moderní řešení šitá na míru našim zákazníkům. To je Benekov, výhradně česká firma s tradicí od roku 1949.

Nejlepší dostupnétechnologie Komplexní řešení

výroby energií Nejlepší technické

řešení

na českém trhu Špičkový servis

po celé ČR Česká firma

a tradice

od roku 1949 Vlastní výzkum

a vývoj VÍCE INFORMACÍ O NÁS

Moderní technologie Benekov

Využíváme nejmodernější technologie. Nabízíme nejlepší technické řešení na českém trhu. Máme vlastní výzkumné a vývojové středisko.

VÍCE informacíKontaktujte nás

Chcete navrhnout ideální řešení?

Zajímá vás cena? Nebo se jen potřebujete na něco zeptat?

Napište nám prostřednictvím formuláře vpravo.

Nebo na mail info@benekov.com. Případně volejte 554 748 008.