ENERGY SAVING BOILER SYSTEM

A long-term trend in the research of boilers for all kinds of fuel is reducing operating costs and increasing the comfort of operation. This trend is general and can be seen in other fields such as cars or standard home appliances.

The firm BENEKOV is the Czech leader in the market of automatic solid fuel boilers

The firm BENEKOV is the Czech leader in the market of automatic solid fuel boilers. The firm has been working on the "energy saving boiler system" over a long period of time. When deciding on investing in any boiler intended for heating of family houses and larger buildings, making decisions cannot be narrowed down only to the source of the heat itself but it is also necessary to take into consideration all the parameters of the heating system. When assessing the advantages of an investment in new boilers it is important to take into consideration all kinds of costs that are related to its operation. To be well informed is comparatively difficult in the heating pipe fitting field because there is no data that can help customers to compare the operation of different types of boilers. When talking about cars, the average fuel consumption is measured per 100 km, however, there is no such comparable data with boilers or heating systems.

Before the implementation of investments in new boilers, Benekov presents its customers with the basic kinds of costs which are related to the operation of the heating system so that they can better assess the usefulness of their investment in new sources. Assessing all the operating costs with different options of investments enables the customer to choose the solution which ensures the lowest operating costs over a long period of time and enables them to create the most efficient and economically most advantageous conditions. The following 4 basic kinds of costs of heating system are:

OPERATIONAL EFFICIENCY OF THE BOILER

The efficiency of automatic solid fuel boilers in accredited testing laboratories is tested by two tests, at 100% and 30% performance. The producers should state the values in manuals so that the customer can objectively compare the parameters for individual products. Nowadays, the highest achieved values of efficiency with automatic coal boilers are about 90%. The tests are performed for 6 hours in an ideal situation. The efficiency, measured in the state testing laboratory, is not the same as the real, operating efficiency measured under normal use of the equipment. It is caused by the fact that during normal use the boiler clogs up with fly ash and gradually decreases its efficiency. From that point of view, the more economical boilers are those with vertical construction of the exchanger. Such construction, by its very nature, does not allow fast clogging heat transfer surfaces and cleaning such a boiler body can be done once in 4 to 6 weeks. On the other hand, all the boilers with horizontal exchangers clogg up quickly. If the user does not clean the heat exchanging surfaces clogged with ash at least once a week, the efficiency goes down rapidly. For performances with 25 kW or higher it is necessary to clean the exchanger twice a week. It especially concerns boilers with cast-iron echanger, but also boilers with steel exchangers, where the clearing area is up front. The user of a boiler can decide, while thinking about the investment, between a boiler with vertical construction with slow clogging the heat exchanging surfaces and a boiler with horizontal construction of the exchanger with quick clogging of the heat exchanging surfaces and with that connected rapid decrease of operating efficiency.

Another important factor to get high operating efficiency is the modulation of boiler performance and use of equithermal regulation. Solid fuel boilers without modulation work in the "gas-brake" mode and mostly during the transition periods in spring and fall, significantly increase the fuel consumption. On the other hand, boilers with the modulation enable automatic adjustment of the feeding time and air supply intensity into the combustion chamber which allows to greatly save used fuel. Equithermal regulation works with differences in outside and inside temperature. Its utilization together with modulation of the performance enable to reduce fuel consumption per heating season annually up to 20% . The customer should check with the producer, whether the control unit of the boiler can modulate and whether the heating system is equipped with equithermal regulation before the investment. Without these elements, the consumption of the boiler room will be about 20 % higher.

INPUT POWER OF THE BOILER

The producers must state the value of the input power of the whole equipment on the nameplate of the boiler; it is objectively comparable data. Input power of automatic coal boilers that are distributed on the Czech market ranges between 38 and 500 W for boilers with 25 kW of the thermal power. The boiler BENEKOV C 26 has extremely low value of power input, which, at its full load, consumes only 38 W of power. This is 7 x less than the majority of boilers that are imported to the Czech Republic from foreign countries. The main difference is that the boilers from the firm BENEKOV are mounted with motors with helical gearbox and majority of models are equipped with ventilators by a German firm EBM with a smooth control of the signal 0-10 V. On the other hand, the majority of boilers from abroad use cheap motors with worm-gear unit with significantly lower efficiency and cheap ventilators without smooth regulation. The bonus for using electro-components of higher quality on boilers is up to seven times lower price on electricity spent when operating the boiler. Through the 15-years long boiler life, you will save approximately CZK 30,000 and more on electricity consumption costs, including the effects of inflation and long-term increase in electricity prices.

INPUT POWER

European legislation keeps on tightening requirements on electricity consumption of all kinds of appliances. The use of electronically controlled pumps and mixing valves with minimal consumption significantly reduces the costs of electricity consumption of the whole heating system. Each boiler room is individual, but when choosing all the appliances with propulsion, it is important to pay attention when comparing their consumption. During the lifetime of the entire heating system you can either save or throw tens of thousands of crowns out of the window based on the choice of appliances.

TIME TO OPERATE AND MAINTAIN THE HEATING SYSTEM

Solid fuel boilers naturally need more operation than gas or electric boilers. The basic, objectively comparable data giving an account of operating requirements is the size of the fuel tank and the volume of the ash-pan. The differences among commonly sold boilers on the Czech market can be doubled. One of the most successful models of the firm BENEKOV, boiler C 16, contains an ash-pan with the volume of 24 liters and 330 liters fuel tank as standard. Customer experience with operation is that according to the intensity of heating in the building and the outside temperature, the boiler enables them to refuel during winter time once in 3 to 5 days; it can be once in 10 days in spring and fall.

To increase the operating comfort, boilers BENEKOV equipped with the control unit Siemens Climatix can be added with the installation of the automatic exchanger cleaning and deashing. None of the Czech producers of boilers on the Czech market offer such a combination for automatic coal boilers.

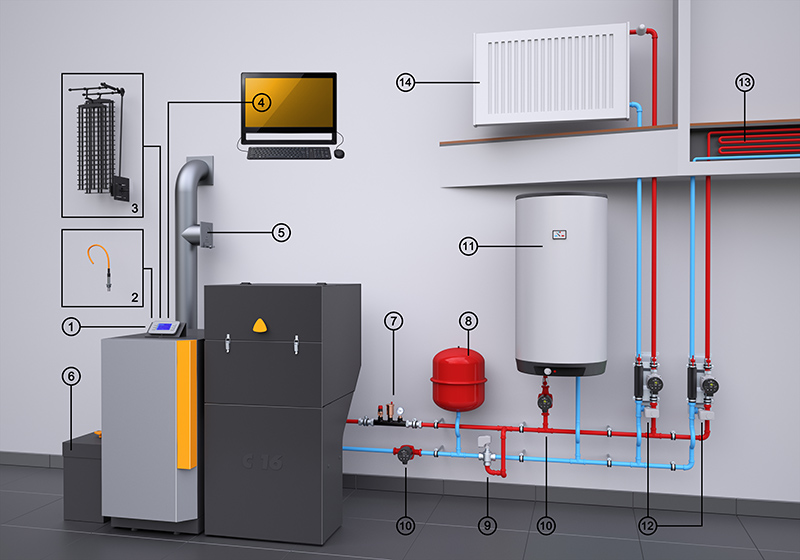

The energy saving boiler system BENEKOV is a complex heating solution with an automatic boiler for coal or pellets designed to minimize all four of the abovementioned cost items.

To achieve minimum operating costs and a minimum number of operators, the below stated elements can be added:

1- The control unit Siemens Climatix

2 - lambda sensor

3 - automatic exchanger cleaning

4 - remote Internet access

5 - chimney damper

6 - ash remover

7 - support kit

8 - expansion vessel

9 - three way mixing valve Siemens

10 - pump Grundfos ALPHA2

11- water heater

12 - hydraulic fixing kit Siemens SUG

13 - floor heating

14 - radiators

The key factor for good regulation of the heating system is the control unit Siemens Climatix with equithermal control of the heat circuits, which, together with the modulating control of the burning process, reduces fuel consumption by 20 % compared to the system with fixed values of the feed and ventilator. Ventilators produced by the German producer EBM Papst, controlled by the signal 0-10 V and motors with a helical gearbox TOS Znojmo, minimize the input power of the boiler comparable to one energy-saving bulb. To increase the efficiency of the whole heating system and get the maximum operating comfort comparable with gas boilers, the boiler BENEKOV can be equipped with, besides other things, automatic deashing and fully automated exchanger cleaning.

When choosing a boiler it is necessary to assess the total costs and maintenance of the heating system. A reasonable investor who does not want to unnecessarily spend money and time for another 15 years, compares all the relevant data and decides on a solution with the lowest operating costs per investment. The energy saving boiler Benekov is a complex solution to the heating system which achieves minimum operating and maintaining costs. A vast network of authorized assembly-service centers provides advice to customers and facilities for consultation prior to the investment in energy saving boilers. These centers can advise the customer with a selection of the most suitable solutions.

Benekov - firma s tradicí

Zkušenost, inovace, flexibilita, komunikace a moderní řešení šitá na míru našim zákazníkům. To je Benekov, výhradně česká firma s tradicí od roku 1949.

Nejlepší dostupnétechnologie Komplexní řešení

výroby energií Nejlepší technické

řešení

na českém trhu Špičkový servis

po celé ČR Česká firma

a tradice

od roku 1949 Vlastní výzkum

a vývoj VÍCE INFORMACÍ O NÁS

Moderní technologie Benekov

Využíváme nejmodernější technologie. Nabízíme nejlepší technické řešení na českém trhu. Máme vlastní výzkumné a vývojové středisko.

VÍCE informacíKontaktujte nás

Chcete navrhnout ideální řešení?

Zajímá vás cena? Nebo se jen potřebujete na něco zeptat?

Napište nám prostřednictvím formuláře vpravo.

Nebo na mail info@benekov.com. Případně volejte 554 748 008.